Consulting and Sales

Gain a competitive edge with LanKorra Consulting & Sales in the SMC, BMC and Compression Molding Industry. LanKorra has over 42 years’ experience in the complete molding process.

These years of experience include raw composite materials from bulk material handling, storage, function, to the mixing. The full production process including the production of your own SMC Paste, compression molding down to the finished product handling and storage.

Take a look at our Consulting page and review the brief list of consulting topics. There are many areas in which LanKorra Consulting can assist your company. Fill out a request form and we’ll contact you within 24 hours.

Let's Discuss

what LanKorra can do for you.

Strong Relationships

LanKorra has strong relationships with the leading Unsaturated Polyester Resign suppliers in the SMC Industry. We also have strong relationships with several other Raw Material Vendors making the review of a clients raw material handling, SMC paste, formula, or packaging process an easier task.

Is your company’s looking for a review of your products costs, or you want to reduce the current supply costs, LanKorra’s relationships with the many vendors and suppliers will be a great asset to tap into.

If LanKorra finds better pricing or product(s) for you, we don’t make you pay more for the information, we include all the information in our reports for you.

If you decide to change to a LanKorra recommended supplier, LanKorra will introduce you and help you ask all the questions about their product, request samples, or set up an on-site visit to your facility.

LanKorra works with your purchasing dept. and the new supplier(s) to lock in the best prices for you. All included with our consulting services, at no extra charge, with no commissions or kick backs from the vendor(s), just good business practice.

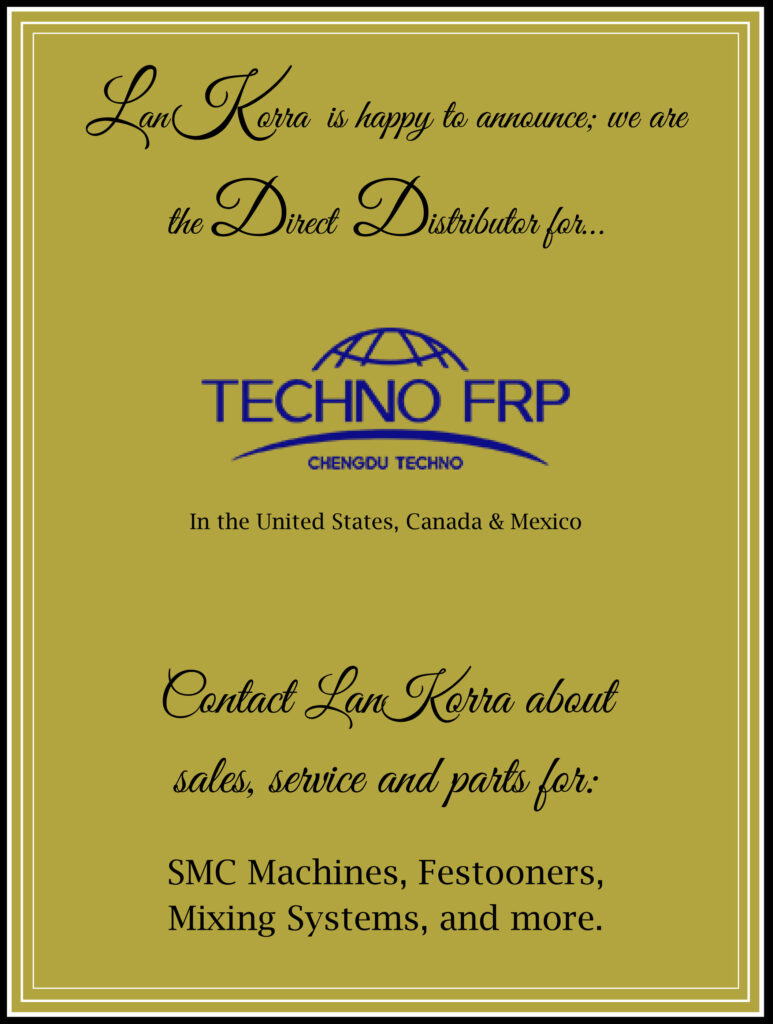

Who is Techno FRP Equipment Co., Ltd.

The SMC Machines produced by Techno FRP Equipment Co., Ltd embody humanization and technology. The products have many users in China and are exported to foreign markets such as South Korea, the Czech Republic, Dubai, Turkey, Egypt, Oman, and India. The excellent product quality and after-sales lifetime service warranty have won high praise from users. And now with LanKorra being a Distributor, our SMC Machines will reach an even broader base of clientele.

With LanKorra being a representative for Techno FRP Equipment Co., Ltd in the United States, Canada & Mexico, the Clients located there will now have the peace of mind knowing there’s a sales, service, and parts distributor in the United States to work with.

If you’re in the market for a small SMC Lab Machine the 600mm will be perfect for your needs. But it doesn’t end there, Techno FRP Equipment Co., Ltd also builds SMC and BMC Machines of all sizes, including the top rated, Fully Automated 1600c SMC Machine that is already fitted with a Bulk Mixing System and Automated Festooner.

Who is Techno FRP Equipment Co., Ltd.

The SMC Machines produced by Techno FRP Equipment Co., Ltd embody humanization and technology. The products have many users in China and are exported to foreign markets such as South Korea, the Czech Republic, Dubai, Turkey, Egypt, Oman, and India. The excellent product quality and after-sales lifetime service warranty have won high praise from users. And now with LanKorra being a Distributor, our SMC Machines will reach an even broader base of clientele.

With LanKorra being a representative for Techno FRP Equipment Co., Ltd in the United States, Canada & Mexico, the Clients located there will now have the peace of mind knowing there’s a sales, service, and parts distributor in the United States to work with.

If you’re in the market for a small SMC Lab Machine the 600mm will be perfect for your needs. But it doesn’t end there, Techno FRP Equipment Co., Ltd also builds SMC and BMC Machines of all sizes, including the top rated, Fully Automated 1600c SMC Machine that is already fitted with a Bulk Mixing System and Automated Festooner.

With LanKorra being a representative for Techno FRP Equipment Co., Ltd in the United States, Canada & Mexico, the Clients located there will now have the peace of mind knowing there’s a sales, service, and parts distributor in the United States to work with.

If you’re in the market for a small SMC Lab Machine the 600mm will be perfect for your needs. But it doesn’t end there, Techno FRP Equipment Co., Ltd also builds SMC and BMC Machines of all sizes, including the top rated, Fully Automated 1600c SMC Machine that is already fitted with a Bulk Mixing System and Automated Festooner.

Click here or on the Sales tab below for mroe details

If you’re interested in more information , fill out the Call Request Form below.

If you’re interested in more information regarding our consulting services, fill out the Consulting Request Form below.

If you’re interested in purchasing an SMC Machine or Accessories, fill out the Consulting & Sales Formbelow.