WHO WE ARE

At LanKorra, we are committed to listening to our clients’ needs. With captured data, our consultant will translate your information into executable processes that fit your business's current and projected volume. Whether it's cost of quality, poor delivery, excessive waste, overseas competition, higher costs related to raw materials, or low productivity, we can assist you in developing a strategy that best fits your projected production and budgetary costs.

WE LISTEN

At LanKorra Consulting we are committed to listening to our clients’ needs. With your data we will translate the information into a plan that can be executed in stages or in one large movement . Whether it’s cost of quality, poor delivery, excessive waste, overseas competition, higher costs related to raw materials, imports or low productivity, LanKorra can assist you in developing a strategy that best fits your projected production and budgetary costs.

STRONG RELATIONSHIPS

We have a strong relationship with the Top Unsaturated Polyester Resin suppliers and other SMC Raw Material providers in the industry. LanKorra also offers to our Clients, Toll Production of SMC for pilot materials, and prototype or production compression molding.

SMC CONSULTING

Our SMC Consulting Services is not based on the development of an SMC Formulas alone. We assist our Clients with developing a Cost Model for a full SMC Facility, an expansion, or to upgrade their current equipment. LanKorra provides our Clients with technical information and pricing for: SMC Machines, PDM’s, Raw Material Mixing Systems, along with Compression Molding Presses, and the Ancillary Equipment that’s needed. We can provide our Clients with equipment sizing recommendations, project planning, and project management.

OUR CLIENTS

A part of our business is striving to be the best for our Clients. We believe in exploring new methods and processes using the Continuous Improvement Process, which is critical to our Clients’ success.

Whether it’s Process Control, Quality, Delivery, or Costs, LanKorra will work with our Client’s Team Members using Value Stream Mapping, Plan for Control, and Cost & Model processes to identify issues with the current manufacturing state, then develop these into opportunities for improvements in Process, Controls, Quality, and Costs, and for increased production.

Our Consultant will use DOE’s, DFMEA, and PFMEA processes to develop solutions that result in consistent and repeatable results.

We also offer our Clients:

- Value Stream Mapping & DOE’s

- Compression Molding Process Training

- Optimized Tool Design & Prototype Development

- Trouble Shooting Techniques and Training

- Process Control Training & Quality Control Specification Development

- Training in the development of SOP, SOW, WBS & Process Work Instructions

Are you looking for a cost-effective SMC material and production solutions? With our SMC fomulation development technology and material modeling, we can develop a solution for you.

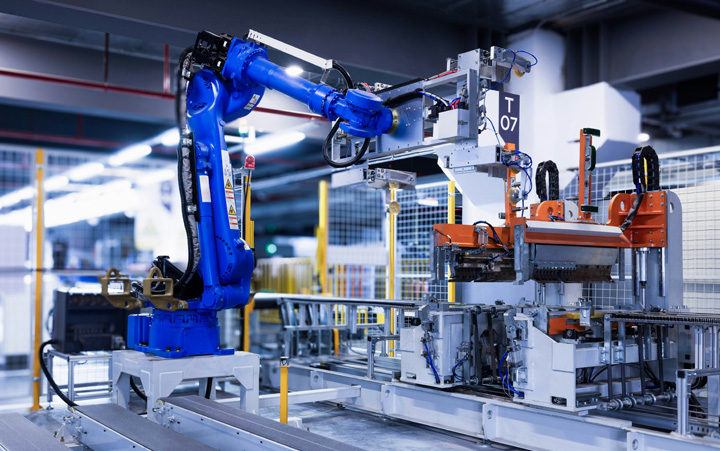

INDUSTRY SAFETY

As EHS affects more of the Industry Work Force, LanKorra has focused on the cost of Health and Safety injuries related to an employee’s continuous and repetitive motion with loading SMC into the press as well as unloading and deflashing molded parts. This area has long been neglected by the Automation world. However, with the advancement in today’s technology there have been significant improvements with Automation.

LanKorra has partnered with several automation companies who have successfully executed SMC Charge Cutting and Stacking Automation and Automated Part Removal and Deflashing with Stacking . These are highly technical automation process that eliminate repetitive injuries to hands and arms, worker absenteeism, part quality variation and down time. Over the last several years we have worked with customers to purchase and install both front and rear automation systems successfully.

Using a Value-Added Calculation, the improvement in production and capacity can reduce the need to purchase additional presses and hire additional labor making automation a more attractive option.